Quality control

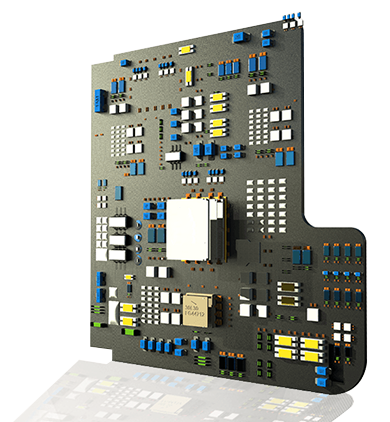

AC bridge

To detect the resistance capacitance and the quality of the first plate, the system will automatically record the relevant inspection information

IQC

Through the self-developed manufacturing execution MES system to build a complete digital quality control scheme

Material room

Each plate of materials is affixed with two-dimensional code, scanned into the warehouse by mobile phone, and the information data is recorded intelligently

Temperature monitoring

The ambient temperature and humidity of the warehouse are collected periodically by sensors to detect anomalies in time