Digital factory

Digital enterprise management, intelligent production line

Continue to integrate “lean production, agile manufacturing, collaborative work” and other advanced management ideas and management models

Intelligent manufacturing

Intelligent device

The foundation of intelligent manufacturing

• Smart devices are an integral part of smart machines and the first link to collect operational data

• Comprehensive integration to achieve deep integration of information and devices

Intelligent machine

Smart, secure and reliable

• Auxiliary machines with greater flexibility, complemented by scalable and reusable solutions

• Ensure timely access to information, increase productivity and enable digital transformation

Intelligent system

The operation system of the enterprise

• Provide production and asset information for production, maintenance and management

• Optimize plant floor assets and provide insight and information to the business

Manufacturing management

Flexible planning

Issue workshop production plan based on order planning mode,In combination with the process route, the plan is broken down to the station

Production informatization

Visualization of production process and equipment, traceability of quality management, Reduce material management costs

Data collaboration

Seamless upstream and downstream business, real-time data sharing, breaking data silos, real-time production progress, information visualization

Overall management of the production process

Open up production information barriers

Production and manufacturing are responsible for the digital management of the production process in the workshop, to achieve the deep integration of information and equipment, to provide complete, timely, and accurate production execution data for the operation and management of the enterprise, to unify the production and manufacturing data sources, to control and optimize the entire production process, to "link the previous to the next", and to eliminate the information island of the enterprise.

With the production process quality information summary and control as the core, they are combined with enterprise operation management to establish an advanced planning system, through barcoding, the use of visual kanban real-time presentation of production and manufacturing information, to create transparent and visual production workshops, through equipment networking, to achieve the interoperability of equipment operation information and self-production, data-driven.

Manufacturing modularization

Procurement, warehousing, logistics, production integration coordination

• Production planning and multi-stage production order execution

• Fine management of production process

• Full chain quality traceability

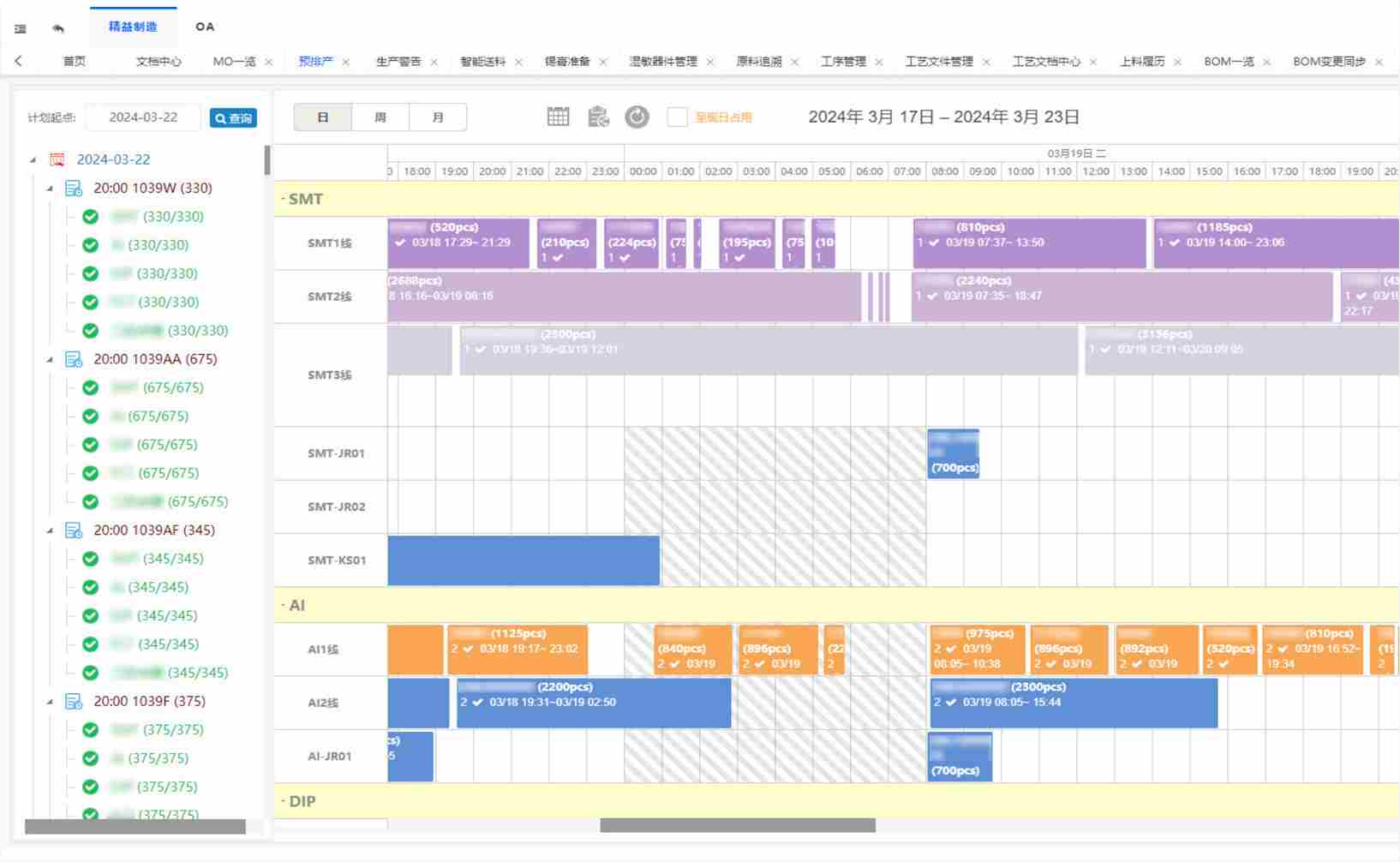

Intelligent scheduling of production

The plan is synchronized with the workshop

• Detailed production scheduling, multi-objective overall optimization

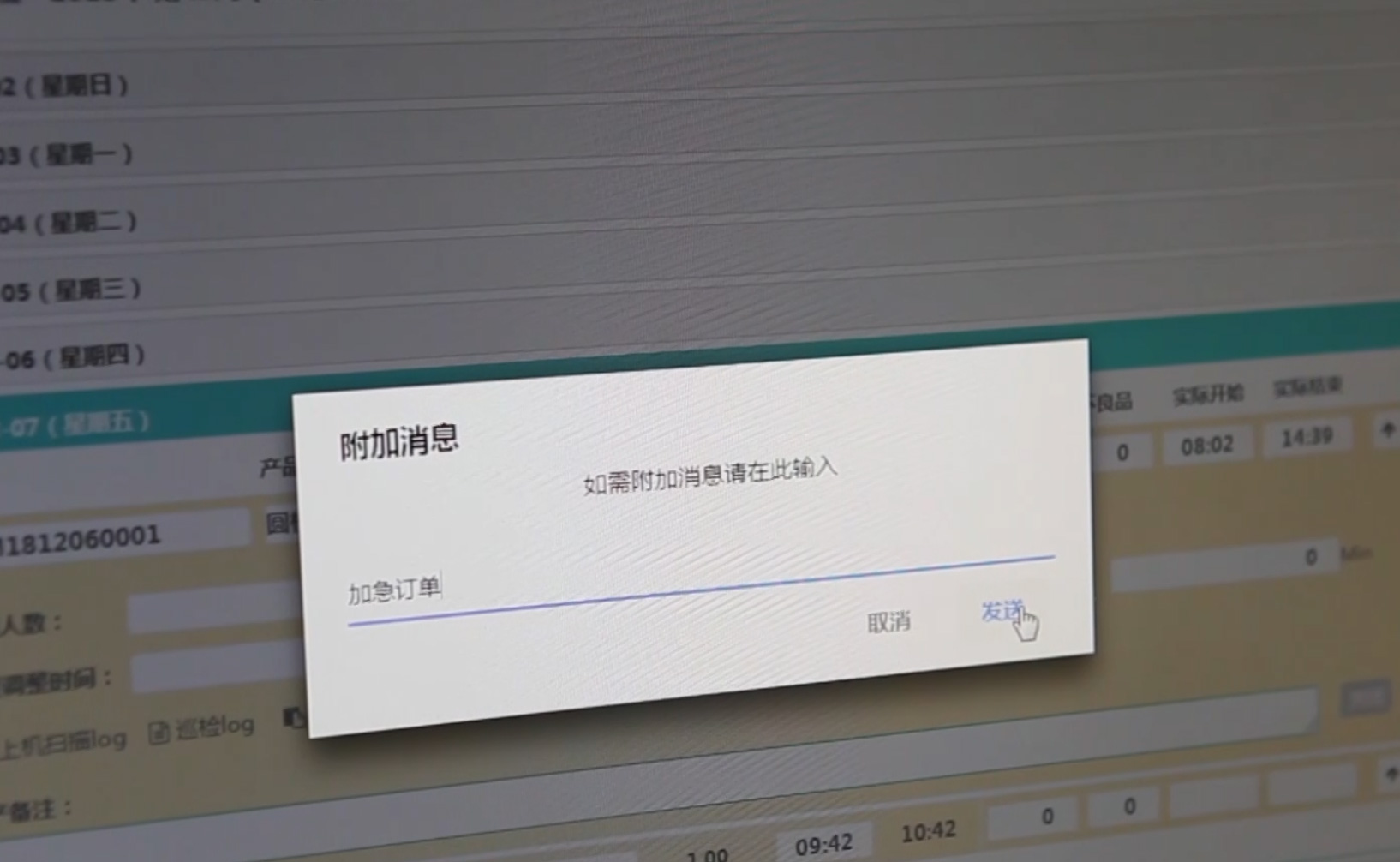

• Adjust the priority of all current orders based on the urgency of the order

• Real-time production reporting and exception warning

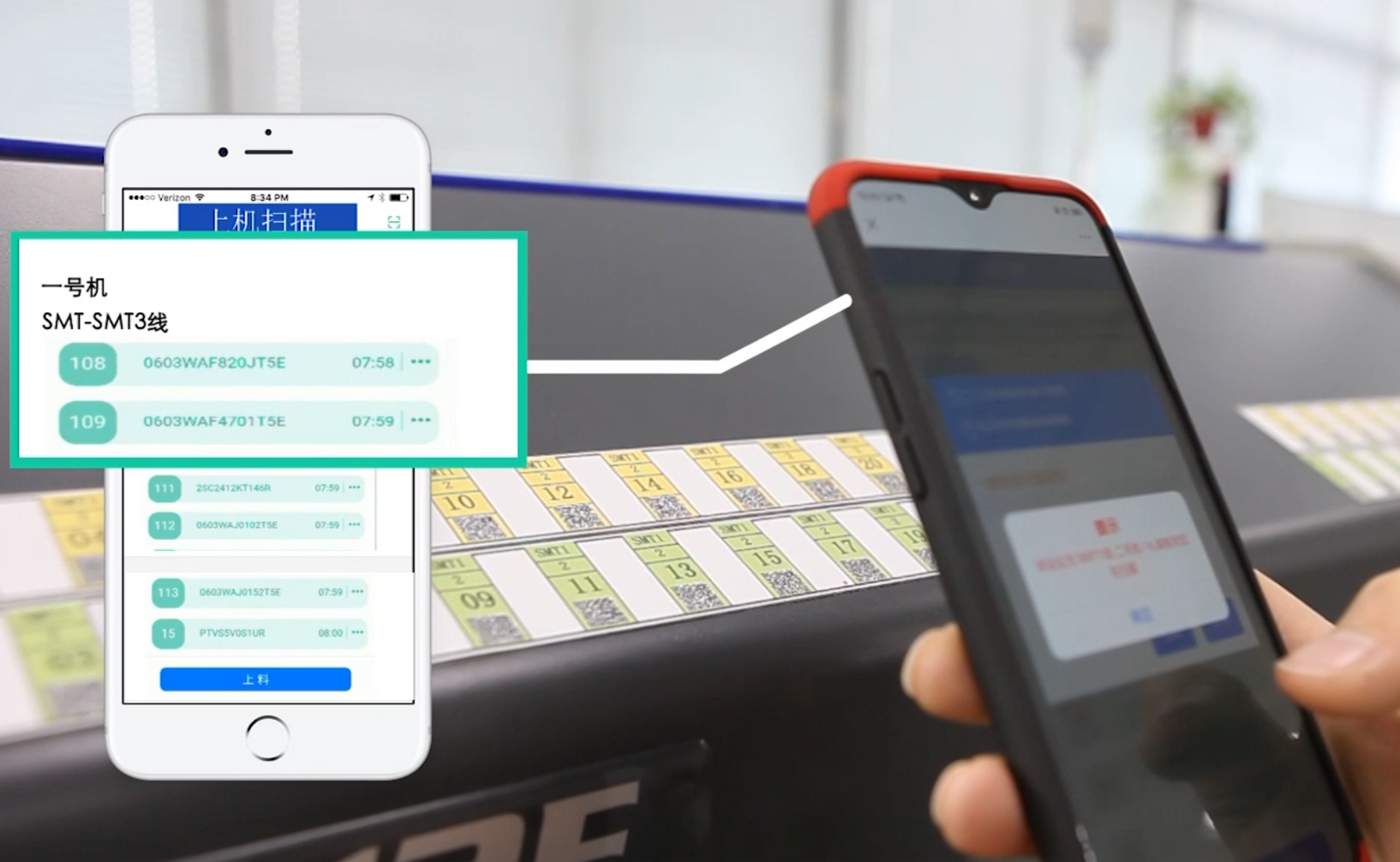

Prevent mistakes and fools

Product life cycle positive and negative traceability

• Scan the QR code of the tray and the corresponding station to prevent mismaterials

• Establish effective data management of all links and increase data support for risk control

• Link up the system data of production and storage

Production data visualization

Intuitive early warning, transparent production

• Timely control of the quantity of good products, production hours and completion ratio

• Timely estimate and remind the supply of materials and semi-finished products

• Real-time monitoring of exception management

Warehouse management

Covering all business links of warehouse management

To realize the comprehensive application of functions such as import and export, inventory transfer, batch management, inventory, quality inspection management, and FIFO, effectively control and track the whole process of warehouse business management through bar codes and electronic labels, improve the information management of enterprise warehousing, improve the efficiency of warehousing logistics distribution and inventory turnover.

Equipment assets

The equipment and fixture are fully controlled based on the idea of lean production TPM

Build the whole process of equipment management, covering equipment maintenance, fault repair, planned maintenance to state maintenance of the full maintenance mode; Including equipment ledger, making maintenance plan, record maintenance results, equipment calibration, maintenance and scrap, and spare parts management, reduce abnormal production caused by equipment and mold failure, improve the overall efficiency of equipment, improve production efficiency.

Quality control

Build a perfect digital quality control scheme through MES to improve product quality assurance

IQC

Improve the quality of incoming materials, reduce the risk of shutdown and improve the stability of product quality, optimize procurement costs, and reduce supply chain risks

IPQC

First inspection, production inspection, and other production process quality control, timely grasp of the product production process, reduce defective products

FQC

Conduct a comprehensive and final inspection and testing of the product quality status to ensure that the product meets the shipping specifications

OQC

Final inspection/shipment inspection is the final guarantee to verify that the product fully meets customer requirements, reducing the probability of customer complaints

Production transparency

Comprehensive data perspective with data transparency at its core, continuously drilling down

Production line panel

Warehouse panel

Market panel

Manufacture panel

E-mail:yewl@chearihi.cn

Phone:0550-3089 819

Address:No. 2588 Fengle Avenue, Chuzhou City, Anhui Province, pilot base