Lean Manufacturing

Intelligent management is the basis, and intelligent manufacturing is the center

A comprehensive manufacturing enterprise that provides global PCB R&D +SMT mounting + material purchasing

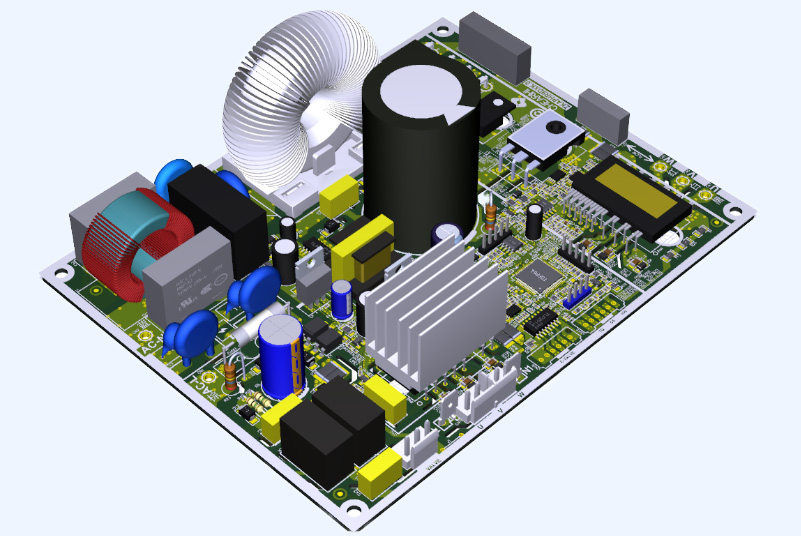

Ultra-clear 3D virtual simulation

DFX-Designed for all aspects of the electronic product life cycle

Unified modeling of product design and production process, simulation and simulation of the entire life cycle of product design on the computer, three-dimensional cutting, measurement and collision detection with verification tools, complete sequencing and automatic assembly path planning simulation in virtual simulation. Decompose complex PCBA systems into multiple independent, well-defined modules, each of which can be independently designed, tested, manufactured, and upgraded.

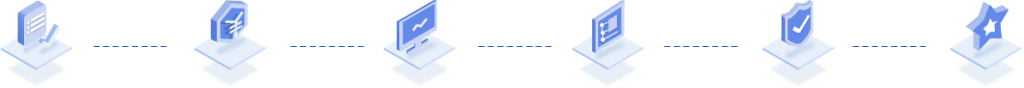

specialization

- Professional home appliance frequency controller R & D and design

- Fully autonomous full set of frequency conversion control algorithm

- Home appliance intelligent control board with intellectual property rights

Strong function

- Dual motor/single motor

- Ac fan/DC fan

- Power frequency/HF/UHF APFC

originality

- PAM

- Pulsation suppression

- Power device noise suppression

High quality

- Won many outstanding quality awards

- Preferred supplier for high-end models

- First pre-installed inspection-free supplier

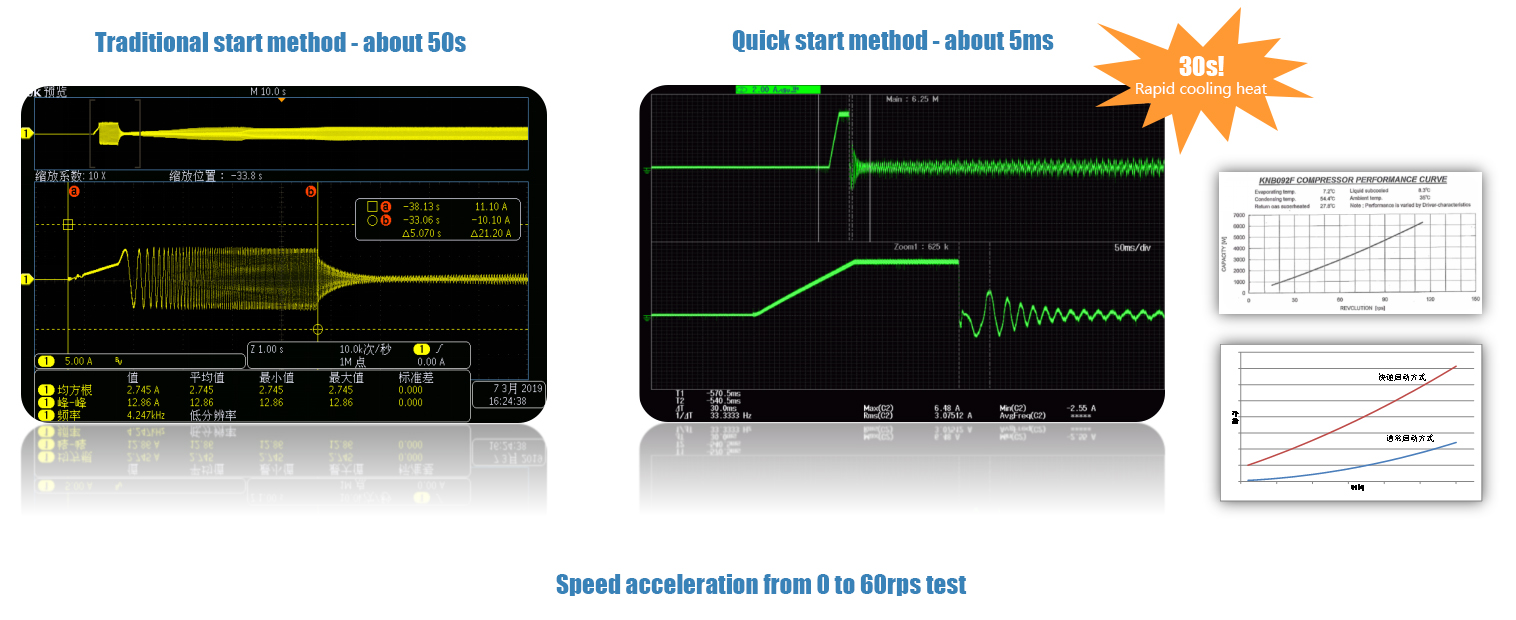

Original speed start-up technology

◉ Forward-looking technology accumulation, cutting-edge technology synchronization, master advanced technical information

◉ Overcome the problems of advanced frequency control board and efficient algorithm research and development

◉ Successfully developed industry-leading home appliance intelligent control board and other products with intellectual property rights

◉ Standardize the research and development management system, strictly check, and do not let go of any mistakes and details

◉ Set up a special platform group to develop a system cooperation division of their own characteristics for existing platforms

Current stability control technology

Senior team, strong research and development technology

More than 30 years of professional R & D experience, from R & D to manufacturing to provide solutions, the best design = "design quality" + "cost control" + "easy commissioning"

One-stop PCBA solution development advantages

Improve production efficiency

Design, procurement, patch plug-in, test assembly, etc. are completed by Chearihi, which realizes seamless connection, avoids communication and coordination between multiple suppliers, and improves product delivery speed and production efficiency.

Reduce costs and risks

Reduce communication and coordination costs, and reduce quality anomalies caused by miscommunication between different suppliers. At the same time, the cost of material procurement and inventory pressure are reduced, and cash flow is released.

Ensure quality consistency

At Chearihi, the traceability and consistency of product quality are effectively guaranteed. Professional quality inspection department is responsible for incoming material inspection to further ensure product quality.

Professional technical support

Chearihi has a professional procurement team that can provide technical support to customers to help them solve technical problems encountered in the process of product design, production and testing.

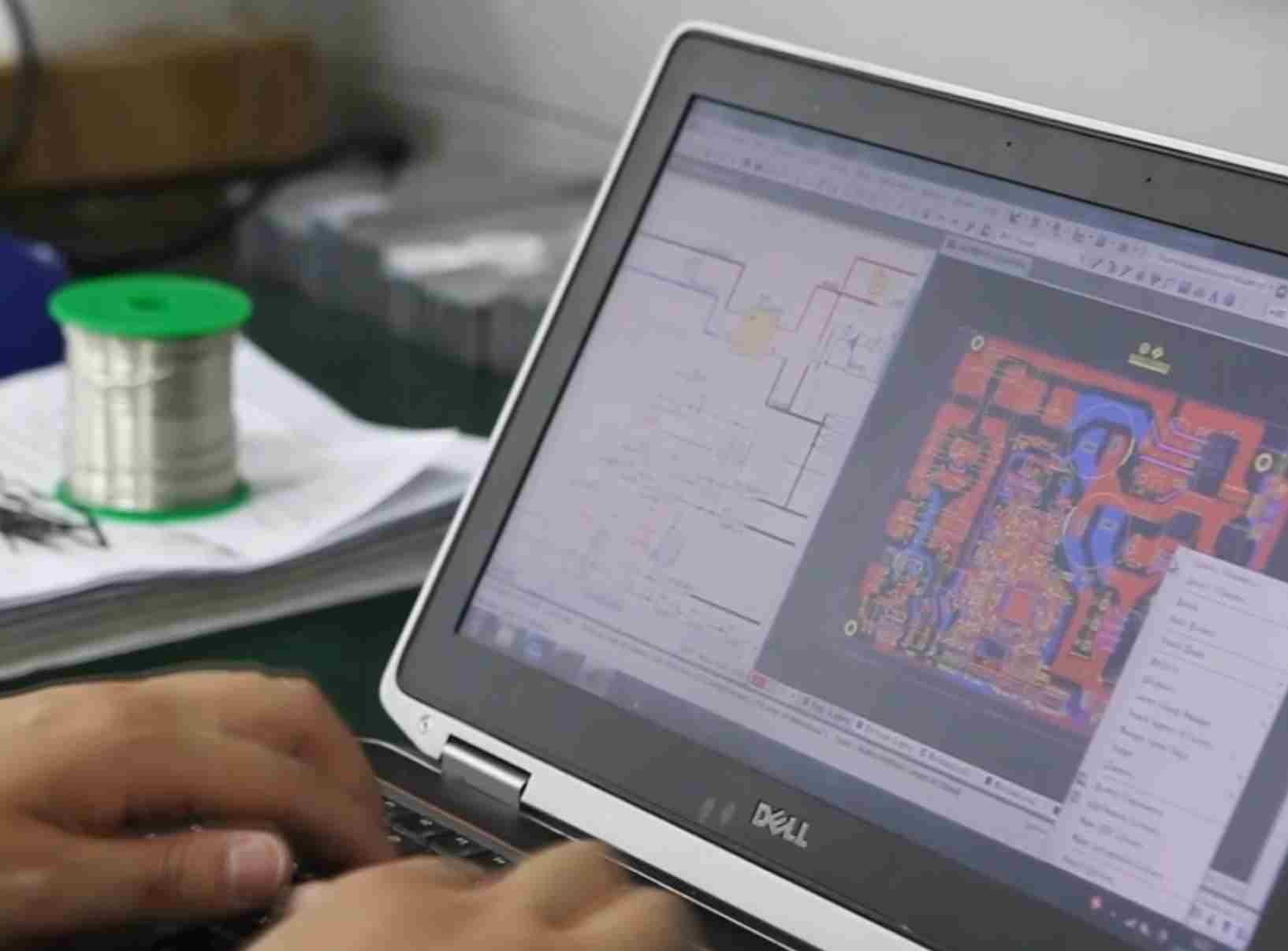

Design process

Information to be provided by the customer

Schematics (schdoc, DSN, or sch) or netlists, structure diagrams (DXF), package libraries (datasheet manual for new packages), design requirements, etc

Customer layout confirmation

Provide layout files and structure files for customers to conduct layout review; The customer confirms the layout rationality, the stacking scheme, the impedance scheme, the structure, the package, and the wiring parameters

Layout and wiring review

According to the design specifications, design instructions, customer design requirements and related CHECKLIST, after the project is started, our engineers will carry out schematic DRC check, structural check and other electrical design requirements, and report to the customer as soon as possible if there is any problem

Design data output

PCB source files, Gerber files, assembly files, steel mesh files, structural files, etc. After the PCB Layout design is completed, our engineers will conduct mutual inspection, including DFM inspection, QA inspection, EMC inspection. After the customer confirms that it is OK, Gerber and other production documents will be issued

digital data Evaluate the offer Start designing Layout validation Overall review Project completion

E-mail:yewl@chearihi.cn

Phone:0550-3089 819

Address:No. 2588 Fengle Avenue, Chuzhou City, Anhui Province, pilot base